Polyurea vs Epoxy Garage Floor: Which is the Best Choice?

A polyurea garage floor is a high-performance coating made from a polymer that provides exceptional durability and protection for concrete surfaces. Known for its quick curing time, flexibility, and resistance to chemicals, stains, and UV damage, it creates a strong barrier that enhances garage floors’ longevity.

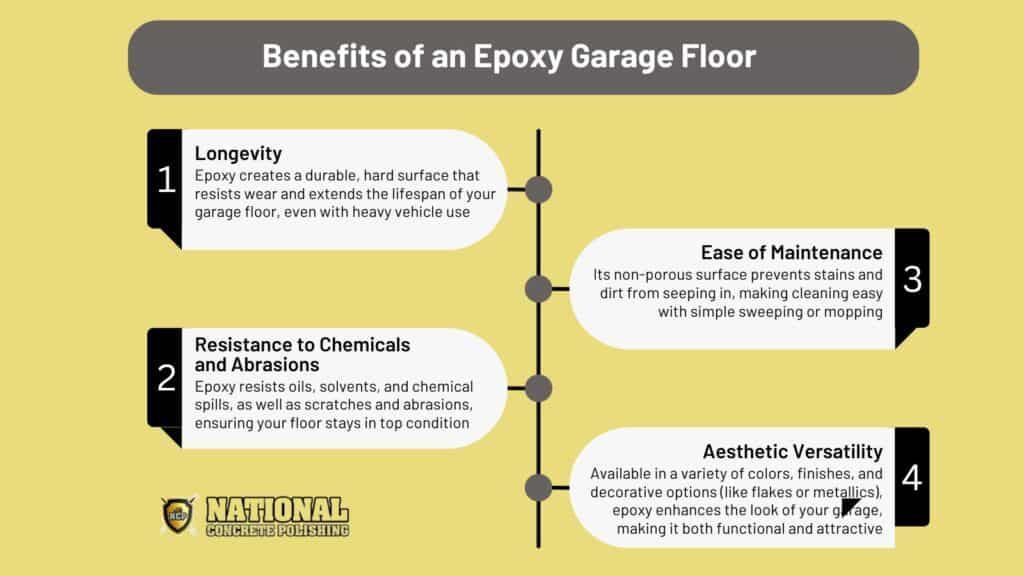

An epoxy garage floor is a durable coating made by applying a thermosetting resin over concrete surfaces. It provides excellent resistance to chemicals, stains, and abrasions, making it ideal for high-traffic areas.

The key difference between polyurea and epoxy garage floors is that polyurea garage floors are more flexible and durable than epoxy, with a faster curing time of about 24 hours. However, epoxy takes several days to cure and becomes brittle over time.

The cost differences between polyurea and epoxy floors include materials and installation. Polyurea coatings are more expensive due to their advanced chemical composition and fast-curing properties. Epoxy floors are more affordable, but their maintenance and recoating requirements add to long-term costs.

The maintenance requirements for polyurea floors are regular sweeping and prompt cleanup of spills to maintain their appearance. In contrast, epoxy floors also need routine cleaning but require specific solutions like hot water and ammonia to prevent staining.

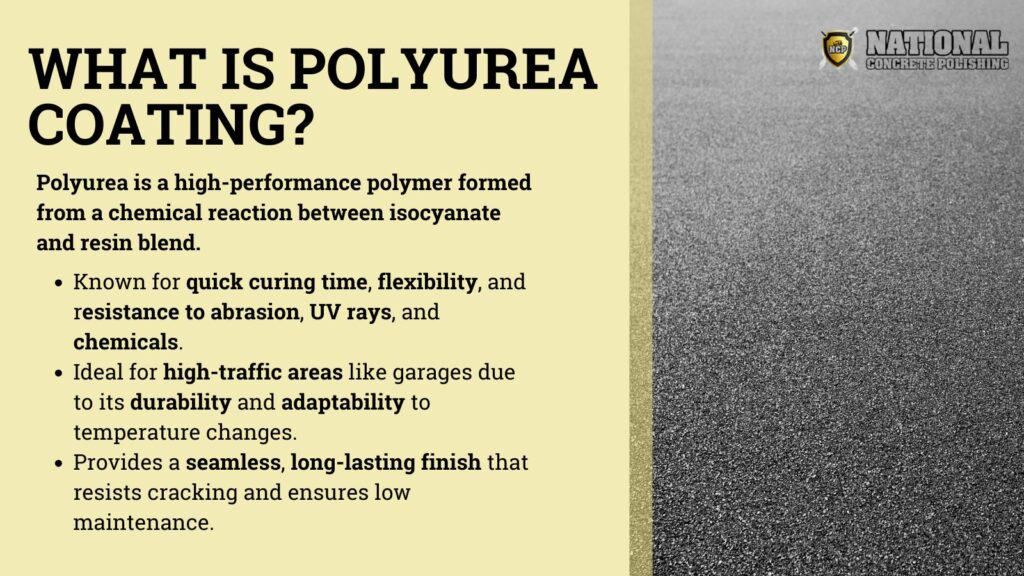

What Is Polyurea Coating?

Polyurea coating is a high-performance polymer formed from a chemical reaction between an isocyanate and a resin blend. It is commonly used in applications such as garage floors and protective coatings for surfaces exposed to moisture and chemicals. Its quick curing time allows for rapid application and makes it ready for use within hours.

One of polyurea’s main advantages is its resistance to abrasion, impact, and UV radiation, making it ideal for high-traffic areas. Unlike traditional coatings, which become brittle over time, polyurea maintains its integrity under stress and adapts to temperature fluctuations without cracking. This combination of strength and flexibility makes polyurea a popular choice for homeowners and businesses seeking long-lasting, low-maintenance solutions.

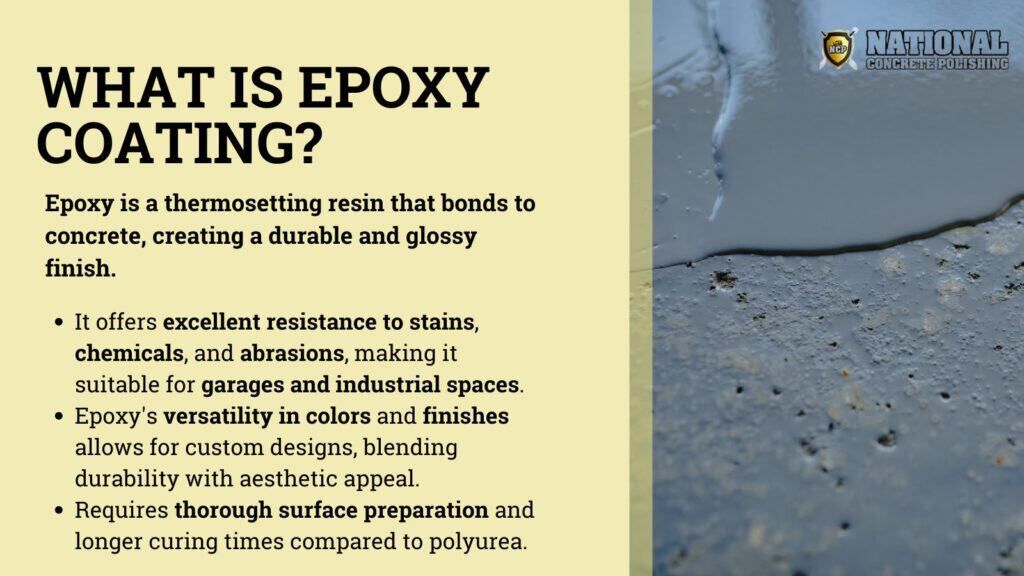

What Is Epoxy Coating?

Epoxy coating is a protective layer made from resin and hardener that forms a strong bond with concrete surfaces. This seamless coating is widely used in garage floors for its durability and polished finish.

Epoxy provides a hard, non-porous surface that withstands heavy traffic and daily wear. Its strength and longevity make it a preferred choice for both residential and industrial spaces.

Epoxy coating also offers aesthetic flexibility with various colors and finishes, combining functionality with visual appeal. Its durability and low maintenance requirements make it a popular flooring solution.

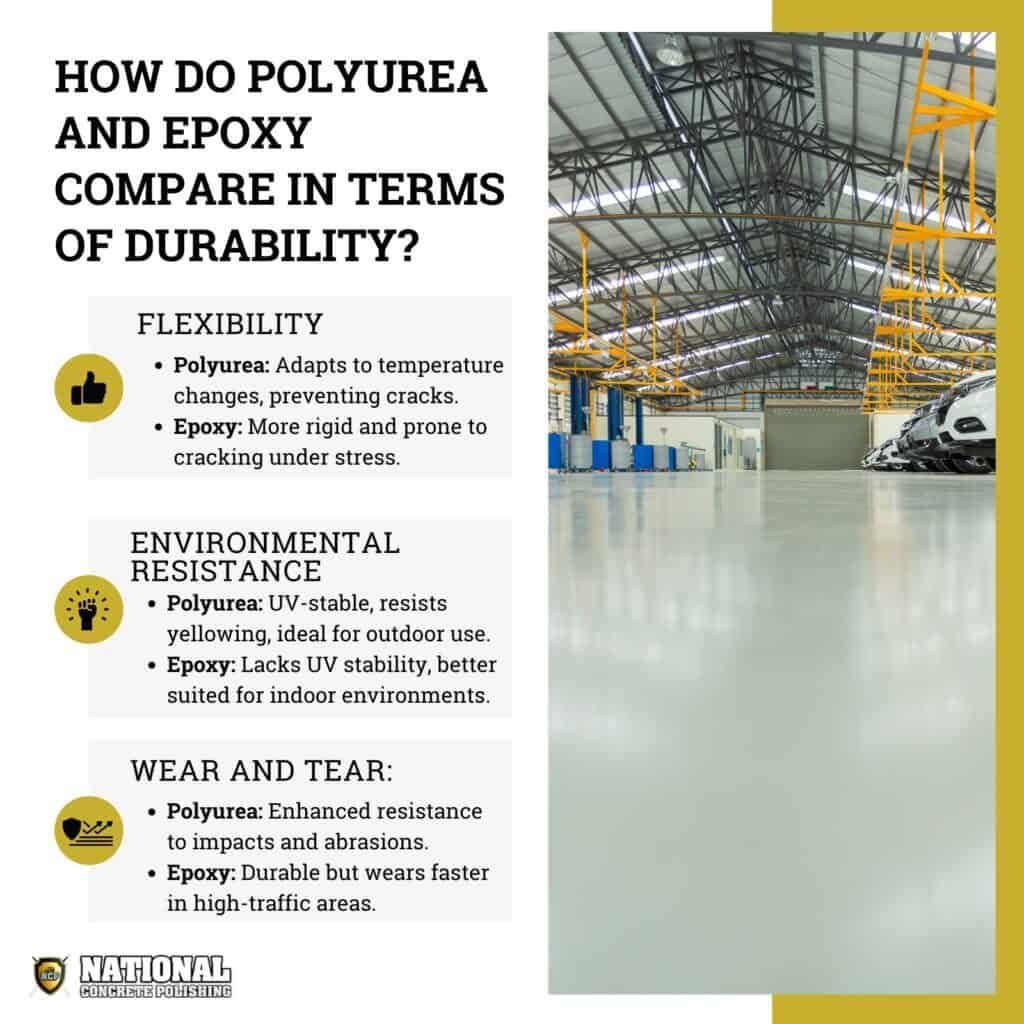

How Do Polyurea and Epoxy Compare in Terms of Durability?

Polyurea and epoxy compare in terms of durability, including their flexibility, resistance to environmental conditions, and ability to handle wear and tear. Both coatings are strong, but their performance varies based on the specific demands of the environment.

The ways by which polyurea and epoxy compare in terms of durability include:

- Flexibility: This is the coating’s ability to adapt to movement, temperature changes, and substrate shifts without cracking or losing integrity. Polyurea is highly flexible, allowing it to expand and contract with temperature fluctuations, which prevents cracks during freeze-thaw cycles. In contrast, epoxy is more rigid, making it prone to cracking if the underlying surface shifts or if exposed to extreme temperature changes.

- Resistance to Environmental Conditions: This is the coating’s ability to withstand external factors like UV rays, moisture, and temperature extremes without degrading. Polyurea excels in UV stability, resisting yellowing or degradation when exposed to sunlight, making it suitable for outdoor use. Epoxy lacks UV resistance and discolor or loses its integrity when exposed to prolonged sunlight, though it performs well in moisture-prone indoor environments.

- Ability to Handle Wear and Tear: This refers to the coating’s capacity to resist damage from abrasions, impacts, and heavy use over time. Both polyurea and epoxy provide excellent protection, but polyurea’s elasticity enhances its resistance to impacts and abrasions, making it less likely to chip or crack. Epoxy, while durable, wear down faster in high-traffic areas or under heavy mechanical stress.

Which Coating Is More Resistant to Chemicals?

Polyurea coating is more resistant to chemicals. Due to its non-porous and flexible nature, polyurea offers exceptional resistance to harsh substances, including oils, acids, and solvents. This makes it ideal for industrial settings and high-chemical-use environments, ensuring long-lasting protection without degradation.

Epoxy also provides strong chemical resistance, particularly against oils, fuels, and cleaning agents. However, it is less effective than polyurea when exposed to aggressive chemicals over extended periods. Polyurea’s superior durability makes it the better choice for areas requiring maximum chemical resistance.

Which Option Offers Better Aesthetic Appeal?

The epoxy coating offers better aesthetic appeal. Epoxy provides a smooth, high-gloss finish that can be customized with metallic effects, decorative flakes, and a variety of vibrant colors. Its polished and professional appearance makes it an excellent choice for creating modern, visually striking surfaces.

Polyurea coatings also offer customization with colors and textures but are more focused on durability than design flexibility. While they provide a clean and functional look, they lack the extensive aesthetic options available with epoxy. Epoxy’s ability to combine functionality with artistic design gives it the edge in aesthetic appeal.

How Do Installation Processes Differ Between Polyurea and Epoxy?

The installation process for polyurea differs from epoxy in its installation time. Polyurea is faster and less time-consuming than that of epoxy. Polyurea coatings cure within minutes, allowing for same-day application and use. The process involves surface preparation, such as cleaning and repairing the substrate, followed by the application of the polyurea in multiple layers. Due to its quick curing time, polyurea minimizes downtime, making it an efficient option for both residential and commercial spaces.

Epoxy, in contrast, requires a more detailed and time-intensive process. Surface preparation involves cleaning, repairing, and etching or priming the substrate to ensure proper adhesion. The epoxy mixture is then applied in layers, with each layer requiring several hours to cure. The curing process takes several days, delaying the floor’s usability. While both coatings require a prepared surface, polyurea’s faster application and curing time make it the more convenient option.

Which Coating Is More Cost-Effective?

Epoxy flooring is the more cost-effective coating option. Due to its widely available materials and straightforward application process, epoxy has a lower initial cost. Its durability and minimal maintenance needs also provide long-term savings, making it an affordable option for both residential and commercial settings.

Polyurea offers superior performance and faster curing times, but due to its advanced chemical composition and application process, it comes at a higher upfront cost. Although polyurea’s long lifespan and durability offset its higher price over time, epoxy remains the more budget-friendly option for most homeowners and businesses.

What Maintenance Is Required for Each Coating?

The maintenance required for polyurea coating includes regular cleaning to remove dirt, dust, and debris that accumulate on the surface. A simple mop or soft brush is enough to maintain its appearance, as the coating’s non-porous nature prevents stains from penetrating.

Polyurea’s resistance to chemical spills also minimizes the need for intensive cleaning, making upkeep straightforward. Occasional inspections for minor wear or damage are recommended to ensure long-term performance, though repairs are rarely necessary due to their durability.

The maintenance required for epoxy coating includes routine cleaning with mild soap and water to prevent dirt and stains from dulling its glossy finish. For areas with heavy foot or vehicle traffic, periodic resealing or recoating is necessary to restore its protective layer and maintain its appearance.

Epoxy requires repairs for any cracks or scratches that develop over time, especially in high-use areas. While it offers excellent durability, proper maintenance is crucial to preserve its smooth and polished look.

Which Coating Is the Best Choice for Your Garage Floor?

Polyurea coating is the best choice for your garage floor because of its flexibility, fast curing time, UV stability, chemical resistance, durability, minimal maintenance, and ability to handle extreme conditions. While epoxy flooring is a popular option for its aesthetic appeal and cost-effectiveness, polyurea offers superior performance in demanding environments.

The reasons why polyurea coating is the best choice for your garage floor include:

- Flexibility: This is the coating’s ability to adapt to substrate movement or environmental changes. Polyurea’s elasticity allows it to expand and contract with temperature fluctuations, preventing cracks and damage in freeze-thaw cycles or high-impact areas.

- Fast Curing Time: This refers to the speed at which the coating sets and hardens. Polyurea cures within hours, minimizing downtime and making the floor ready for use the same day, which is particularly useful for time-sensitive projects.

- UV Stability: This is the coating’s resistance to damage from sunlight exposure. Polyurea does not yellow or degrade under UV rays, making it ideal for outdoor garages or spaces with direct sunlight exposure.

- Chemical Resistance: This is the surface’s ability to withstand exposure to harsh substances. Polyurea is highly resistant to oils, solvents, and other chemicals, ensuring long-term protection and minimal surface degradation even in industrial settings.

- Durability: This is the coating’s ability to handle wear and tear over time. Polyurea resists heavy impacts, abrasions, and mechanical stress, making it suitable for high-traffic areas and garages with heavy equipment or frequent vehicle use.

- Minimal Maintenance: This refers to the minimal effort required to keep the surface in good condition. Polyurea’s non-porous surface repels dirt, stains, and spills, reducing the need for extensive cleaning or repairs over time.

You might also like